Tanks vs Bladders: Why it’s time to rethink effluent storage

Before you commit to a bladder system, here’s what you need to know.

In New Zealand’s dairy industry, the conversation around effluent storage is shifting. With increasing expectations from regional councils and a broader push toward sustainable farming, choosing the right infrastructure has never been more important.

Among the many options out there, bladders are often seen as a quick and cost-effective solution. But while they may tick some boxes on paper, their performance in real-world farming conditions raises a few red flags especially when compared to tanks or properly lined ponds.

If you’re weighing up your options, here are three key reasons to think twice before investing in a bladder system for effluent storage.

1. Loss of pumpable volume over time

Bladders are sealed systems, which means once effluent goes in, there’s no way to remove the solids that gradually settle inside. Over time, these solids build up, reducing the amount of usable (or pumpable) volume the bladder can hold.

Here’s the issue: storage requirements, as calculated using the Dairy Effluent Storage Calculator (DESC), are based on having a certain volume available for regular use. So if your consent requires 500,000L of effluent storage, a 500,000L bladder might meet that need in year one but by year two, that same bladder might only have 450,000L of usable volume due to solids buildup. That drop in capacity isn’t always obvious, but it still puts you at risk of non-compliance.

2. Structural and environmental risks

Bladders have been involved in several failure events here in New Zealand, some with serious environmental consequences. While failures can happen for various reasons, one recurring issue is UV damage.

Many bladders are manufactured overseas in regions like Europe where UV exposure is much lower than in New Zealand. When these materials are placed in our harsher, high-UV conditions, degradation can happen faster than expected. If a rupture occurs, the resulting spill can lead to major cleanup costs and compliance issues. If a product isn’t designed for New Zealand conditions, it may not last the distance.

3. No access for maintenance

Unlike open tanks or lined ponds, bladders offer no practical way to inspect or maintain the system once it’s in use. There’s no access for agitation, no visibility of sludge buildup, and no straightforward way to remove solids.

That lack of control makes long-term planning difficult. If you’re aiming to stay compliant over the lifespan of your effluent system, being unable to monitor or maintain it effectively is a significant disadvantage.

Effluent storage isn’t just about capacity, it’s about reliability, durability, and having control over your system. While bladders may appear cost-effective upfront, they can come with hidden costs down the line, from reduced storage volume and limited maintenance options to the potential for structural failure.

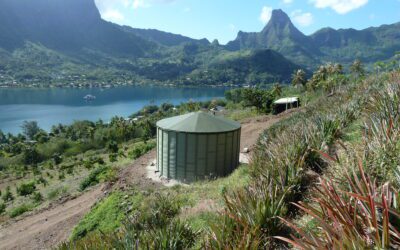

Tanks and engineered lined ponds, on the other hand, are purpose-built for the demands of effluent storage in New Zealand. They provide access for maintenance, can be built to suit a range of site conditions, and most importantly they’re built to last.

Check out some more helpful blogs below

Why is water security important?

Clean, uncontaminated water is essential for life, yet it is often taken for granted. It supports human health, agriculture, industry, and ecosystems. Water shortages can have widespread economic and health impacts, particularly during...

Seven intriguing facts about KlipTank

Check out these seven interesting facts you may not know about KlipTank 1. Neil Peterken - The visionary behind KlipTank Neil Peterken, the inventor of KlipTank, has spent much of his career in the road transport industry. His innovations...

Why is water security so important in the Pacific Islands?

The critical role of water security in the Pacific Islands The Pacific Islands face some of the lowest levels of access to safe drinking water, sanitation, and hygiene. According to the 2023 Joint Monitoring Program, the region is falling behind in...