Seven intriguing facts about KlipTank

Check out these seven interesting facts you may not know about KlipTank

1. Neil Peterken – The visionary behind KlipTank

Neil Peterken, the inventor of KlipTank, has spent much of his career in the road transport industry. His innovations include developing the first hydraulic variable-height house-moving trailer, curtain-siders for truck and trailer units, and founding Roadrunner trailers.

In 2007, Neil set out to create a revolutionary liquid storage solution. His goal was to design a product that:

- Could be packed onto a 1200 x 2400 pallet

- Could be cross-stacked into an ISO container

- Was cost-effective, potentially made from recycled plastic

- Could be transported via a small truck or car trailer

- Was easy to assemble with unskilled labour and minimal tools

- Could withstand New Zealand’s harsh UV rays

- Allowed for customisable diameters, heights, and volumes

- Met regional council requirements for environmentally friendly dairy effluent storage

Since then, KlipTank Limited has refined these ideas, creating a modular storage tank that holds various liquid products in sizes up to 6 million litres. The design ensures that the same components can be used across different tank sizes. A KlipTank arrives as a kitset, allowing for easy transportation and rapid assembly within days.

2. Sustainability at its core

KlipTanks are designed with sustainability in mind. Not only are they almost 100% recyclable at the end of their lifespan, but they also incorporate recycled materials in their construction. Even during manufacturing, offcuts and waste materials are sent back to raw material providers for recycling. This approach minimises environmental impact right from production.

3. Versatility across industries

KlipTanks are used in diverse industries, storing a wide range of materials. While commonly used for water, effluent, and wastewater, they also store:

- Whey and Proliq

- Molasses

- Leachate

- Bark for filtration systems

Interestingly, KlipTanks have also been featured in movies and can be dismantled and stored in a container for later use. They are even being considered for aquaculture (fish farming) and diver training with a 6m deep tank.

In the dairy industry, KlipTanks serve both farm-level effluent storage and processing facility wastewater and whey storage. They are also widely used for raw and potable water storage by councils, individual landowners, marae, and rural communities. Other applications include:

- Mining and gas industries

- Mushroom growing

- Golf course irrigation and fire water storage

- Horticulture (e.g. kiwifruit and apple farming)

4. Adaptable to any location

One of the standout features of a KlipTank is their ability to be installed almost anywhere. Thanks to their flat-packed nature, they have even been assembled in the basements of existing apartment buildings. In response to increasing fire regulations, some buildings have required fire water storage tanks to be retrofitted. Since the buildings were already in use, components had to be carried down stairwells or taken in elevators to reach the basement!

5. Relocatable

KlipTanks can be dismantled and reinstalled elsewhere, making them ideal for dynamic industries. The movie industry frequently relocates them for filming needs, and dairy farms benefit from their adaptability. If a farm rebuilds or moves its dairy shed, the KlipTank can be taken down and reassembled in a more convenient location.

Additionally, if a farm expands and the existing tank becomes too small, it can be dismantled and sold, making room for a larger, more suitable unit.

6. Global presence

KlipTank’s innovative storage solutions extend beyond New Zealand. Their tanks are found in locations worldwide, including:

- Hawaii – Effluent storage

- Marshall Islands – Water storage (including a UN project)

- Thailand – Water storage

- Australia – Water storage

- Papua New Guinea – Water storage

- Kiribati – Water storage

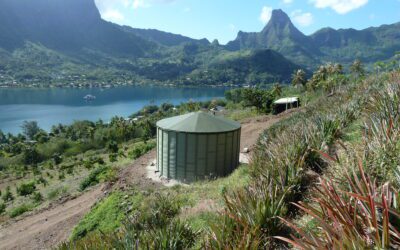

- Tahiti – Water storage

- Fiji – Water storage

- Norfolk Island – Water storage

- Chatham Islands – Leachate storage

7. Proudly New Zealand-Made

KlipTank is committed to supporting local industries. Almost all tank components are manufactured in New Zealand, ensuring high-quality production while boosting the local economy.

KlipTank is more than just a storage solution – it’s an innovative, adaptable, and sustainable answer to liquid storage challenges across industries. Whether for dairy effluent, potable water, or even movie sets, KlipTank continues to prove its versatility and efficiency on a global scale.

Check out some more helpful blogs below

Tanks vs Bladders: Why it’s time to rethink effluent storage

Before you commit to a bladder system, here’s what you need to know. In New Zealand’s dairy industry, the conversation around effluent storage is shifting. With increasing expectations from regional councils and a broader push toward...

Why is water security important?

Clean, uncontaminated water is essential for life, yet it is often taken for granted. It supports human health, agriculture, industry, and ecosystems. Water shortages can have widespread economic and health impacts, particularly during...

Why is water security so important in the Pacific Islands?

The critical role of water security in the Pacific Islands The Pacific Islands face some of the lowest levels of access to safe drinking water, sanitation, and hygiene. According to the 2023 Joint Monitoring Program, the region is falling behind in...